Search

The Difference Between Sand blasting and Vapor Blasting

Sand blasting

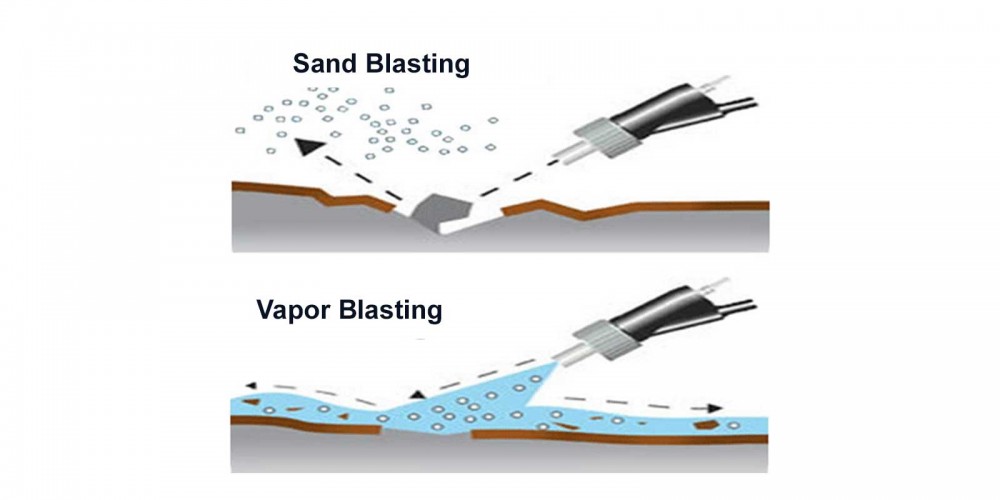

Sand blasting, likewise alluded to as rough blasting, is a hardcore surface prep technique that includes utilizing pressurized air to coercively move sand particles or other grating materials toward surfaces. Notwithstanding eliminating old paint, earth, pollutants, rust, and consumption, sand blasting makes another surface profile that improves the grip between the substrate and the new layer of paint. Thus, the defensive coatings will last more. Preceding sand blasting, it is basic to precisely adjust the blasting hardware and select the right blasting media for every application. Blasting media is isolated into hard abrasives, for example, aluminum oxide, silicon carbide, glass beads, steel grit, and steel shot, and soft abrasives, like plastic beads, walnut shells, and baking soda.

While hard abrasives are utilized to plan steel and other hard metal combinations, soft abrasives are more appropriate for eliminating old paint, soil, and pollutants from both soft and hard metals, just as substrates made of fiberglass, elastic, plastic, composites, or wood. For instance, soft abrasives can securely eliminate flotsam and jetsam, fouling, old paint, rust, and erosion from modern gear, for example, stockpiling tanks, storehouses, and hardware, without harming the substrate. Despite the fact that sand blasting conveys an effective surface prep strategy, it frequently requires enormous amounts of blasting media and creates a lot of residues. Contingent upon the particulars of each paintwork, sandblasting tasks can essentially build the general expense of a modern artwork project and add to more waste that should be discarded.

Besides, cautious thought should be given to security. The modern painters who perform sandblasting activities should wear sufficient PPE that incorporates respirators and ear assurance. Additionally, appropriate residue assortment frameworks are fundamental in the encased zone to forestall fires because of residue aggregation.

Vapor Blasting

Vapor blasting is a non-forceful surface prep strategy that has been explicitly created for applications requiring better wraps up. Joining a slim film of water with fine blasting media, this method can eliminate earth, impurities, rust, erosion, and old paint from a wide scope of surfaces. Since the flood of water and the blasting media have a delicate cleaning impact even on fragile surfaces, vapor blasting diminishes the level of surface disfigurement and gives a great completion. The water additionally goes about as a flushing specialist that forestalls the collection of blasting media on a superficial level being readied.

Contrasted with sand blasting machine, vapor blasting lessens rough utilization. Consequently, it conveys a more savvy surface prep choice. Also, the slim film of water essentially brings down residue discharges, stifling the encompassing residue. This limits the effect of the vapor blasting procedure on any bordering exercises that may be completed at the same time. Since vapor blasting offers a harmless to the ecosystem strategy for giving foreign substance-free surfaces and uses restricted measures of water, it has gotten the go-to decision for some, painting projects. Coming down to security, vapor blasting can be done both in open and encased spaces with negligible PPE necessities. Also, it takes out the danger of residue fires.

One of the disadvantages of vapor blasting is that it can quicken the erosion cycle. Albeit both sandblasting and vapor blasting can mess consumption up, the metal surfaces arranged by vapor blasting will in general erode quicker. To hinder the consumption cycle, and erosion repressing preliminary ought to be applied when the surface has dried out. Control of impact media can likewise be testing. Contingent upon the constructions being set up by vapor blasting, it tends to be hard to hold the water with all the lingering blasting media.