Search

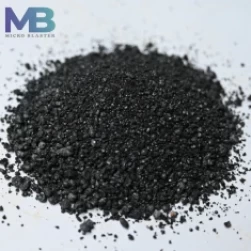

Copper Slag in Faridabad

The Copper Slag can be an abrasive blasting grit composed of granulated Slag made out of metal smelting procedures. The Slag made available from this process is deemed well suited for blast cleaning of metal and stone/concrete surfaces and removing mill scale, rust, old paint, grime, etc.

Product Details:

| SHAPE OF COPPER SLAG | ANGULAR SHAPE |

| SIZE OF COPPER SLAG | 0.5-1.5 mm |

| PRODUCT TYPE OF COPPER SLAG | NATURAL STONE |

| COLOR FAMILY OF COPPER SLAG | BLACK |

Also Read about : Cut wire shots

In recent years, shipping activities developed, have raised an urgent environmental concern related to the use of copper slag for sales as a grit blasting machine for removing rust from the surface of the ships. Copper slag blasting can be either dumped or recycled as secondary material. Therefore, an environmental study, taking into account the potential release of HMs from BCS, should be carried out in order to provide essential information to select the most ‘‘environmentally friendly’’ management options of these slags: reuse, recycling, or controlled disposal.

Uses of Copper Slag

- Refineries

- Shipyards

- Offshore petroleum rigs

- Tanks builders

- Metal fabricators

Copper Slag Blasting

The exertion of solid waste is a challenge for the civil and environmental engineers to extract the waste from different industries to excel the sustainable development, and within the same time, copper slag matching with the value of these materials. Copper slag blasting may be a repercussion obtained during smelting and refining of copper. The waste copper slag is often used as abrasive blasting machine tools, construction , sand blasting machine, and ballast. Despite the escalating rate of reusing copper slag grit, a large amount of its annual production is disposed of in dumps or stockpiles so far. One of the dominant potential applications for reusing copper slag blasting is in cement and concrete production. When it's introduced in concrete as a replacement material, copper slag grit reduces the environmental pollution, space problem and also reduces the value of concrete. However, further additions of copper slag caused reduction within the strength thanks to a rise of the free water content within the mix.

Many people have investigated the specification of copper slag abrasive blasting within the assembly of cement, mortar, and concrete as mixed with lime stone powder, dust, cement replacement, use as partial replacement of coarse, and fine aggregates. The use of copper slag in cement and concrete provides potential environmental benefits for all related industries, particularly in areas where a substantial amount of copper slag price is produced.

Copper slag for sale, a by-product of the metallurgy process used for obtaining copper from copper ore in Bor, Serbia, contains mainly silicon, iron, calcium, and aluminum oxide. Due to such properties, it's disposed of in landfills.

Applications of Copper Slag

- Metallurgical surgeries

- Blast cleanup of metal along with also stone/concrete surfaces

- elimination of mill scale, rust, old paint, and grime.

- Copper slag mainly used in sand wrought iron.

- Copper slags can be utilized from the bronze welding (metal welding) of aluminium, solid iron, malleable iron, and mix welding of substances in precisely the same or closely equivalent makeup.

- designed for usage within bronze welding (metal welding)cast iron or malleable iron

- They are used for Outdated steel exterior coating cleansing, rust removal, and strengthening the similar.

- A wear-resistant flooring mixture might be produced from tough flooring tiles such as ribbons, squares, and other non-flooring.

- Right after processing, that is fine. It might employ a denim coat and spray on an assortment of sophisticated usage.

- Engineered slags can be utilized for their aluminum and aluminum metal filler sticks.

Is copper slag blasting hazardous?

Copper slag abrasive can contain high concentrations of heavy metals, particularly arsenic, cadmium, tungsten carbide, and lead, resulting in their classification as hazardous wastes. The concentrations of arsenic in copper slags depend upon the furnace use during smelting, 62 being higher during the conversion step of the copper ore.Which size of copper slag is used is depends upon the size of the sand blasting nozzle. Various sizes of sand blasting nozzle are used as per the required working output.

Copper Slag Manufacturers in Faridabad

Sand blasting Hopper manufactures premium quality Copper Slag. We are the best Copper Slag Manufacturers in Faridabad. Prominent manufacturer and exporter of various Industrial Products. We are the best copper slag manufacturers in Faridabad and also ISO Certified Company and A Govt. of India Recognized Export House.

Our Products range includes an abrasive thermal spray gun, sand blasting machine, abrasive garnet, metalizing wires like aluminum wire and zinc wire, grit blasting machine, metalizing gun, etc.

Copper Slag Prices in Faridabad

We have the best offering for Copper Slag Prices in Faridabad. We offer the premium quality products in the current market which match the international quality standards. Checkout the Copper Slag Prices in Faridabad. Also checkout the prices of other premium quality products Coating Booth, Thermal Spray Booth, Coating Booth, Grit Blasting Cabinet and etc.